Alfa therm Hazardous/industrial waste incinerator is a specialized designed to safely and effectively dispose of hazardous and industrial waste through combustion. Hazardous waste refers to any waste material that poses a substantial threat to human health or the environment due to its chemical, biological, or physical properties.

Here are some key points about hazardous/industrial waste incinerators:

1. Purpose:

The primary purpose of a hazardous/industrial waste incinerator is to destroy hazardous substances and reduce the volume of waste. Incineration is an effective method to thermally decompose hazardous materials and convert them into inert ash and gaseous byproducts.

2. Waste Types:

| WASTE GENERATOR / DESTROYER | WASTE TYPE |

|---|---|

| HW (TSDF) | Industrial waste, oily rags, waste oil, Spent Solvents, Paint sludge waste, liquid chemical, contaminated waste water, |

| Chemical Manufacturers | Acids and Bases, Spent Solvents, Reactive Waste, Wastewater Containing, Organic Constituents |

| Printing Industry | Paint Solutions, Waste Inks, Solvents, Ink Sludge Containing |

| Petroleum Refining Industry | Wastewater Containing ,Benzene & other Hydrocarbons ,Sludge from Refining Process |

| Leather Products Manufacturing | Toluene and Benzene |

| Paper Industry | Paint Waste Containing, Ignitable Solvents |

| Construction Industry | Ignitable Paint Waste, Spent Solvents, Strong Acids and Bases |

| Metal Manufacturing | Sludge containing , Cyanide Waste, Paint Waste |

We'll guarantee our incinerator can discard all modern waste and can surpass every one of your assumptions concerning limit, result and cost adequacy.

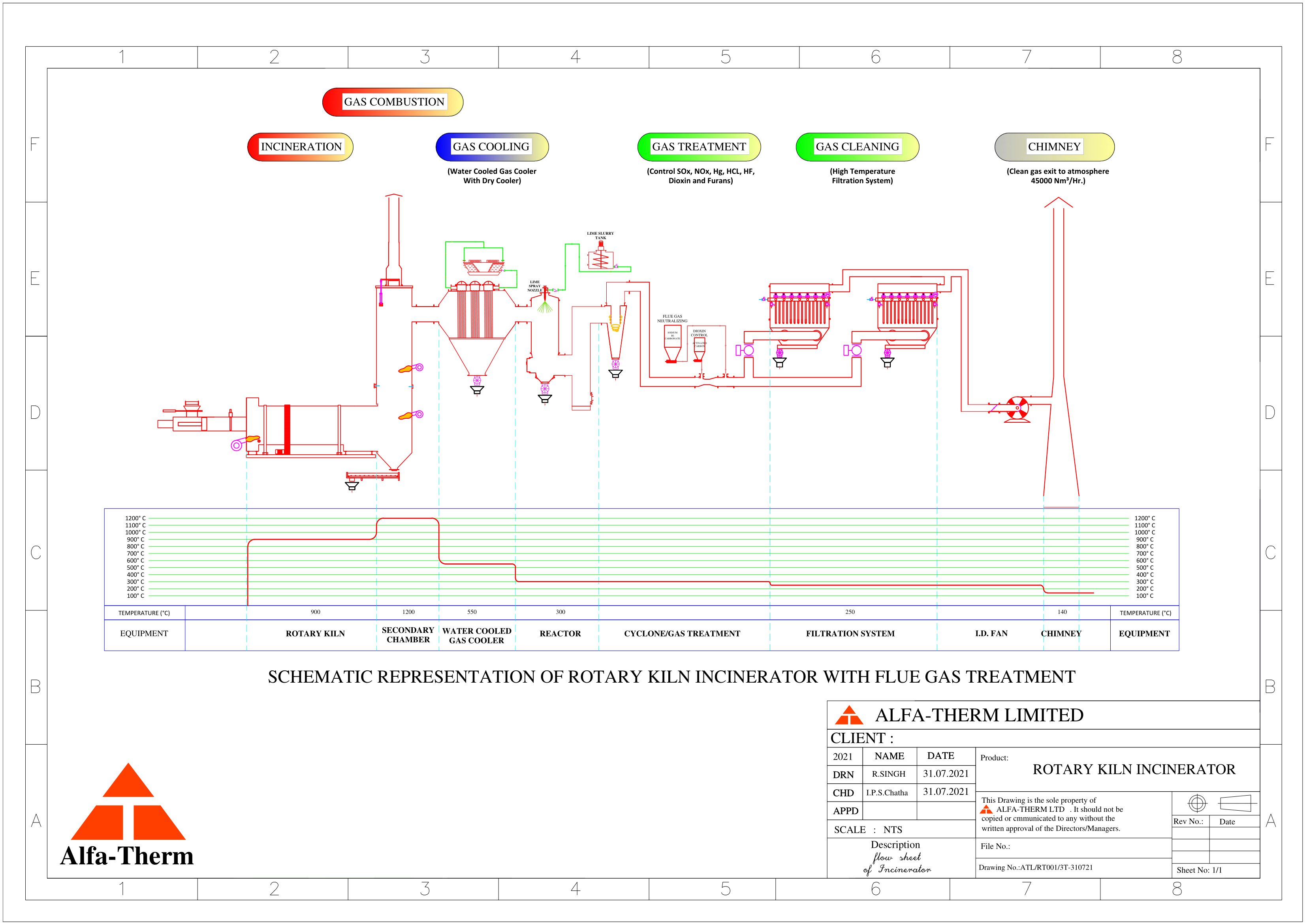

3. Incineration Process:

The incineration process involves subjecting the waste to high temperatures within specially designed incinerators with 2 seconds residence time waste burning at temperatures typically ranging from 800 to 1,200 degrees Celsius (1,472 to 2,192 degrees Fahrenheit) to ensure complete combustion and destruction of hazardous constituents. The combustion process is carefully controlled to optimize efficiency and minimize emissions.

Static hearth design upto 250 kg/hr

Rotary kiln design for bigger capacity (250 kg/hr to 3000 kg/hr) and 24 x 7 plant operation

Liquid waste Incinerator

Fluidized bed Incinerator

4. Air Pollution Control:

Alfa Therm Incineration releases controlled pollutants into the atmosphere, including gases and particulate matter. To mitigate the environmental impact, hazardous/industrial waste incinerators are equipped with advanced air pollution control systems. These systems employ technologies such as scrubbers, filters, and electrostatic precipitators to remove pollutants and ensure compliance with strict emissions regulations.

Two type of Air pollution control system provided based on client requirement

- 1. WSS design: wet scrubbing Technology

- 2. DSS design: Dry scrubbing Technology

Regulatory Compliance:

The operation of hazardous/industrial waste incinerators is subject to stringent regulations and guidelines imposed by government agencies; We ensure that the incinerators meet specific standards for any local or international regulation such as EPA, EU 2000/76/EC (or 2010/75/EU) emissions control.

Additional feature

- 1. Energy recovery (hot air, thermal oil, steam, hot water, electricity) based on client requirements

- 2. Fully automated PLC and SCADA control system provide

- 3. Various type waste Feeding: Conveyor / Hydraulic Ram Pusher/ DFDV feeding system,HCV liquid injection system, LCV liquid waste injection system.

- 4. Emission: Alfa-Therm Incinerator can achieve any Local or International regulation such as EPA, UAE, Egyptian, EU 2000/76/EC (or 2010/75/EU) including Indian.

- 5. Installation : Easy with the help installation manual and drawings/By ATL's engineer

Technical Specifications

| Model | HWR-250 | HWR-500 | HWR-750 | HWR-1000 |

|---|---|---|---|---|

| Capacity | 250 | 500 | 750 | 1000 |

| Vol. of Combustion chamber | 6.3 - 8.75 | 12.8 - 15.5 | 19.2 - 25 | 26 - 31 |

| Inert % (depending on wastes) | 3% to 5% | 3% to 5% | 3% to 5% | 3% to 5% |

| Combustion Efficiency | 99.999% | 99.999% | 99.999% | 99.999% |

| Operating time | 24 x 7 | 24 x 7 | 24 x 7 | 24 x 7 |