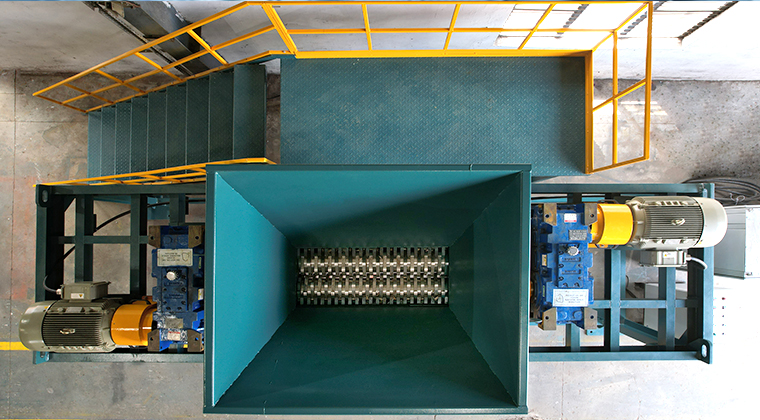

Alfa Therm twin shaft shredders are designed to operate at lower speeds, utilizing high torque and the tearing, crushing and shearing actions between counter rotating, opposing blades. This results in minimal power consumption and reduced noise when compared with other types of shredders, whilst still achieving high throughout rates and maintenance cost.

Alfa ThermLtd. Shredders are particularly suited to the size reduction of bulky materials.

Twin Shaft shredder Series:

- 1. LT - Series: For light duty application with throughput up to 200 Kg/hour.

- 2. MT -Series: For medium duty application with throughput up to 800 Kg /hour.

- 3. HT -Series: For heavy duty application with throughput up to 8000 Kg/hour.

- 4. UHT -Series: For ultra-heavy-duty application with throughput up to 30000Kg/hour.

- 5. RSS-Series: For uniform size reduction with frame mounted rotary screens.

Advantages & Features:

- • Robust and heavy designed for maximum throughput with minimum down time.

- • Remote monitoring.

- • Automatic lubrication system.

- • Online Input or output weighing system with cloud data.

- • Blades wear detection system.

- • Live cutting chamber video access.

- • HMI & PLC control for easy access.

- • Online service and fault alerts.

Application Industries:

Waste Management, E-waste recycling, Cement Plants, Wasteto Energy Plants, Tyres Recycling, Bio-Methanation Plants, Ethanol Refinery, Plastic Recycling, Paper Mills, EPR Facilities, Material Recovery Facilities etc.

Application Waste type:

- • RDF (Residual derived fuel)

- • MSW (Municipal solid waste)

- • WEE (Waste from electrical & electronic components)

- • AFR (Alternative fuels & Raw Material)

- • Tyres

- • Biomass

- • Rice Paddy Straw

- • Empty Fruit Basket

- • Medical Waste

- • Wood waste

- • Aluminum Scarp & Cans

- • Food Waste

- • Plastic & Steel Drums

- • Electrical Cables

- • Rubber Waste

- • Packaging Waste & Printing Roll rejects

- • Pulper rope

- • FRP waste

- • Hazardous waste